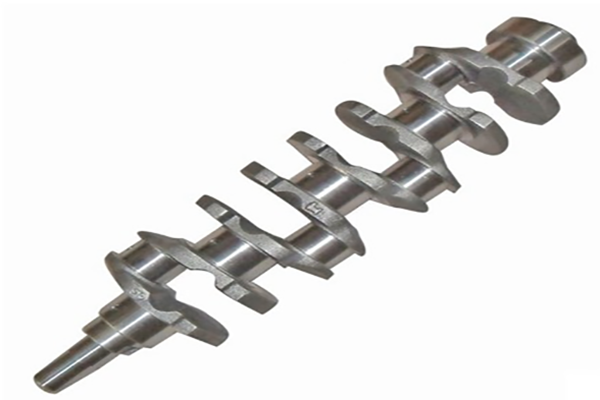

Crankshaft ultrasonic cleaning machine, a good way to quickly clean crankshaft

Browse Volume:997 Classify:Support

Crankshaft is one of the important parts of automobile and motorcycle engines. In order to better improve the working performance of vehicle engines. The key part of crankshaft. In addition to the higher requirements for dimensional accuracy, shape and position accuracy, surface roughness and journal hardness. The requirements for cleanliness indicators are also becoming more and more stringent. This is because once the crankshaft is not cleaned up to the standard, the lubricating oil circuit of the engine will be blocked by dirt or particles, resulting in the destruction of the oil film of the moving pair. At least, it will aggravate the wear of components. And at worst, it will cause the scratch of the engine bearing bush, which will reduce the working performance of the whole machine or scrap it.

Since the cleanliness of the crankshaft plays an important role in improving the overall performance of the engine. Cleaning the crankshaft in the process of assembly, production or maintenance of motor vehicles and motorcycle engines has naturally become an essential process. So, what kind of cleaning equipment can meet the cleaning requirements of high cleanliness of crankshaft? No, ultrasonic cleaning equipment can solve this problem.

The cleaning of crankshaft mainly includes two aspects:

one is the cleaning of the outer surface of crankshaft; Second, crankshaft oil hole cleaning. At this stage, there are still many methods for cleaning the crankshaft, such as high-pressure water cleaning, manual cleaning, large flow flushing, oil hole brush, etc. These are very traditional cleaning processes, and each has its own advantages and disadvantages. Due to the irregular shape and uneven surface of the crankshaft, these traditional cleaning methods often have omissions during cleaning, the stains attached to the corners are not cleaned in place, the cleaning efficiency is also relatively low, and the cleaning effect is also questionable. The use of crankshaft ultrasonic cleaning equipment can solve these problems, but also reduce the investment and use cost of process equipment.

And the crankshaft ultrasonic cleaning machine has a wide range of applications:

It is applicable to the cleaning of almost all metal parts and components such as oil pump, carburetor, cylinder block, cylinder head, cylinder head, crankshaft, gearbox, valve cover, connecting rod, etc. in various automobile parts manufacturing enterprises, automobile overhaul plants and boring and grinding processing.

Cleaning advantages of crankshaft ultrasonic cleaning machine:

1. Complete cleaning and low cost

Using this equipment can effectively clean the carbon, colloid, sludge and other oil stains on the inner and outer surfaces of the cylinder block and cylinder head, and achieve the effect of renovation. With this equipment. All lubricating oil passage holes and some cooling systems can be thoroughly cleaned, and the engine performance can be greatly improved. The product is cleaned with tap water and detergent, which can be recycled for a long time, and the cleaning cost is very low (1:10 of gasoline brushing).

2. High efficiency

Greatly improve the cleaning efficiency, which is 5-10 times that of traditional immersion cleaning, heating and spraying cleaning methods. It adopts high-voltage transistor transducer and special bonding process, with strong ultrasonic, supporting long-time and high-intensity operation.

3. Safe and reliable

When the output power increases by more than 15%, the potential of the transducer can be brought into full play. Working voltage AC220 ± 10V. With overvoltage, overcurrent, output short circuit and other protective measures. It has the functions of frequency fine-tuning and automatic frequency tracking, which can achieve ideal results under different working conditions. It drives the cleaning fluid to form a fine reflux. So that the dirt of the workpiece can be quickly removed from the surface of the workpiece while being stripped by ultrasound. So as to improve the cleaning efficiency. With the function of stepless power regulation, the output power can be adjusted continuously by 10% – 100% to meet the requirements of various cleaning objects. Split design of water and electricity, safe and reliable operation. Ultrasonic power and temperature control can be adjusted and set at will.

GranboSonic

GranboSonic

Hello!